- Home

- Products

- Underground Drill Rigs

- DKZ-10 Underground RC Drill Rig (Reverse Circulation Drilling)

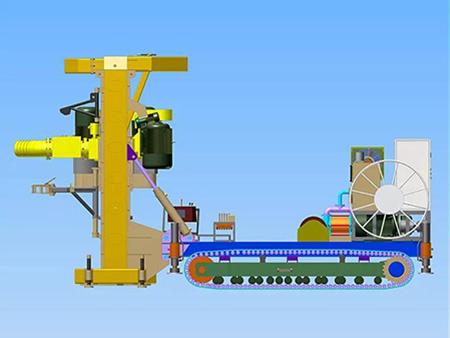

DKZ-10 Underground RC Drill Rig (Reverse Circulation Drilling)

The DKZ-10 underground RC drill rig plays an important role in the construction of subway stations and other areas where operation space is limited. It is an extremely lightweight rig with a reliable performance that is easy to accurately and efficiently move. With a maximum drilling diameter of 1.8m, it is suitable for foundation construction of long tunnel projects.

Parameters- Drilling Depth:150 m

Drilling Diameter:600-1800 mm

Power Head Rotational Speed:0-12 r/min

Drill Rod Diameter:Φ299

Drill Rod Length:1620 mm

Power Head Torque:≧45 KN.m

Feed System Lifting Capability:≧200 KN

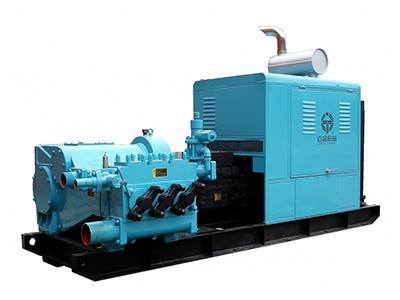

Displacement of Mud Pump ≧600 m3/h

Mud Pump Suction Distance ≧7 m

Water Ring Vacuum Pump:SK-9

Ultimate Pressure:6700Pa - Pumping Power:182 kw

Mud Pump Power: 55KW

Power Head Rotation:22KW*2

Vacuum Pump:15KW

Assistant Winch:1.5KW

Heat Dissipation of Hydraulic System:0.55KW

Dimension (length×width×height)

Transport Dimension: 6150×2300×2750 mm

Working Dimension: 6150×2300×3940 mm

Weight:about 16000 kg (Excluding tools)

- The DKZ-10 drill rig is driven by a frequency conversion motor as the main drive and by hydraulic transmission as the assisting power. This saves energy, reduces costs, and ensures an easy operation. Construction parameters such as rotational speed, rotary torque and power head speed can be displayed and adjusted under different customer requirements.

- All components are on the track chassis. With a simple wireless remote control or operated by workers on the drill rig, it features a self-walk function. .

- It has a long feed stroke of 1700mm with a low disassembly frequency, which increases labor efficiency and decreases labor intensity.

- With a frequency conversion drive, the drill rig is continuously viable according to stratum and slagging, thus avoiding drilling accidents.

- Utilization of a frequency conversion motor and reducer casing for rotation provides a large output torque, thus achieving a constant torque and power operation.. It is continuously viable according to stratum and bore diameter.

- The feed system is driven by an independent frequency converter, and is able to float and hover via a depressed drilling through a winch, wirerope and pulley blocks. Its feeding speed is continuously viable.

- In normal drilling, the hydraulic system has a low power consumption and produces little heat, which ensures the reliability of hydraulic system components.

Inquiry Form

China Geological Equipment Group Co., Ltd.

Add.: 5th Floor, Botai Mansion, No. 221 Wangjing Xiyuan, Beijing 100102

Contact Us:

Tel: +86-510-83769831

English

English