Oilfield Tools

-

- Steel Sucker Rods Grade sucker rods are made of high-quality alloy steel,withmoderate strength, great plasticity and good corrosion resistance etc. Grade C sucker rods can be used in weakly acidic media without sulfurized stress fracture.

-

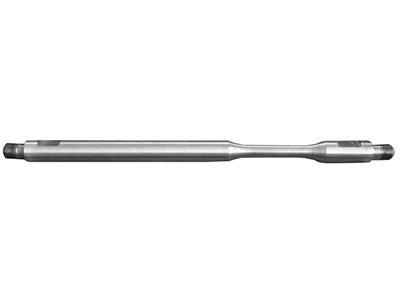

- Polished Rod CGEG produces two types of polished rods: general polished rod and end upset polished rod. All polished rods are made of high-quality alloy cold-draw steel, with great strength and toughness, smooth surfaces and extended lifespan.

-

- Sinker Bars Sinker bars are used between sucker rods and oil pumps. With its weight, the sinker bar keeps the sucker rods at tension and at the center of the oil pipe, so as to prevent the sucker rod from bending in the oil well and causing friction with the internal wall. The sinker bars comply with API Spec 11B Standards.

-

- Couplings (Class T) Couplings include sucker rod coupling, reducing coupling and polished rod coupling. There are five specifications: 5/8", 3/4", 7/8", 1" and 1-1/8". All the couplings comply with API Spec 11B and SY/T5029 Standards. The couplings are made of high-quality carbon steel or alloy steel.

-

- Drive Sucker Rod Drive sucker rod is a special sucker rod we develop for the latest market demands. The materials of drive sucker rod are the identical with those of the sucker rods of the same grade. Drive sucker rods are used in the screw pump in oil well. The drive sucker rods bear both tension and torsional load.

-

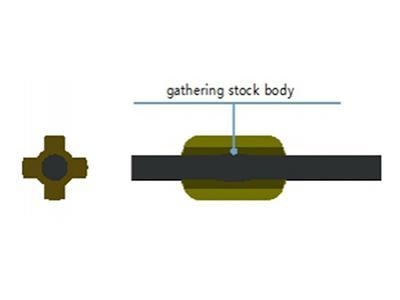

- Centralized Sucker Rod Centralized sucker rod, also known as orientating sucker rod, is a kind of special rod. The only structural difference between centralized sucker rod and ordinary one is that there are multiple nylon rod guides molded or installed on the centralized sucker rod.

-

- Couplings Couplings include sucker rod coupling, tapered coupling and polished rod coupling. The internal threads at both ends of the sucker rod couplings are identical and they are used to connect sucker rods of the same size or sinker bar with sucker rod thread.

-

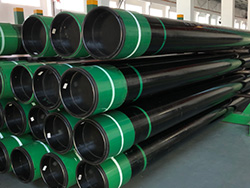

- Casing Casing is a series of steel pipes that are set inside the drilled wells to stabilize well or boreholes. Every well is equipped with different casing according to drilling depth and geological condition. Our casings meet API Spec 5CT, API Spec 5B, PSL1, PSL2 and PSL3 standards. The bore diameter of customized products is between114.30 and 339.72mm.

China Geological Equipment Group Co., Ltd. (CGEG) was established in 1987. Our products are suitable for use in the main procedures of geological exploration including ground geophysical exploration, geological drilling, core sampling, well inspection as well as chemical analysis of the minerals. We have products such as drilling rigs, drilling tools, geophysical instruments, analytical instruments and so on. We, CGEG actively expanding our engineering contracting and trading business as well as constructing a foreign trading platform. CGEG has successfully undertaken about 50 national technological innovation projects and this allows us to provide our customers from all over the world with high quality geological exploration equipment.

Inquiry Form

China Geological Equipment Group Co., Ltd.

Add.: 5th Floor, Botai Mansion, No. 221 Wangjing Xiyuan, Beijing 100102

Contact Us:

Tel: +86-510-83769831

English

English